Add to Cart

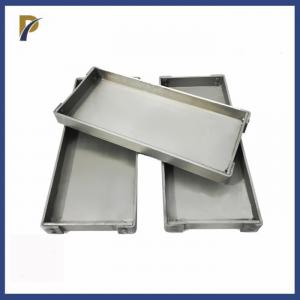

Molybdenum boats are used in the glass industry for glass melting furnace applications. They are vessels made of high-purity molybdenum with excellent heat resistance and chemical stability and dimensional stability, able to withstand the high temperature and corrosion of molten glass, and provide stable and reliable vessels. They help ensure uniform heating and quality control of molten glass and are widely used in various links in the glass industry.

| Grade | Main chemical content% | Impurity content(<%) | |||||||||

| Mo | Ti | Zr | C | La2O3 | C | 0 | N | Fe | Ni | Si | |

| Mo1 | Remain | — | — | — | — | 0.01 | 0.007 | 0.002 | 0.01 | 0.002 | 0.01 |

| TZM | Remain | 0.40~0.55 | 0.06~0.12 | 0.01~0.04 | — | — | 0.03 | 0.002 | 0.01 | 0.005 | 0.005 |

| MoLa | Remain | — | — | — | 0.4~1.2 | 0.01 | — | 0.002 | 0.01 | 0.002 | 0.01 |

High temperature resistance: Molybdenum has a very high melting point, about 2623°C (4753°F), which can withstand and carry glass melt in high temperature environment without melting or deforming.

Chemical stability: Molybdenum boats have excellent chemical stability, which can resist the erosion and dissolution of glass and other molten substances, thus prolonging the service life.

Wear resistance: The molybdenum boat can resist the abrasion and wear of molten glass, and has a long service life.

Thermal conductivity: Molybdenum has good thermal conductivity, which can effectively transfer heat to the glass melt, keep the temperature uniform, and help control the quality of the glass.

Dimensional stability: molybdenum boats have a low coefficient of thermal expansion under high temperature conditions and good dimensional stability, which helps to keep the shape and size of the container unchanged.