Add to Cart

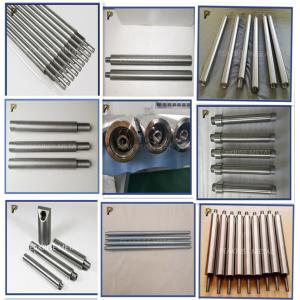

Electrode Of 99.97% Purity Molybdenum For Electric Glass Melting Furnace

1. Specifications Of electrode purity molybdenum for electric glass melting furnace:

Mo electrodes

(1) dia4~120mm,length 2000mm max

(2) Density: 10.2g/cm3

(3)Surface roughness: < 1.6

(4)Purity: >99.95%,99.97%

(5)Application temperature environment:1600~1800℃.

Common size of molybdenum electrode:

| Diameter(mm) | Length(mm) |

|---|---|

| 10 (+/- 0.02) | 1000~2000 |

| 12 (+/- 0.02) | 1000~2000 |

| 15 (+/- 0.02) | 1000~2000 |

| 18 (+/- 0.02) | 1000~2000 |

| 20 (+/- 0.02) | 2000 |

| 25 (+/- 0.04) | 2000 |

| 30 (+/- 0.1) | 2000 |

| 35 (+/- 0.2) | 2000 |

| 40 (+/- 0.3) | 2000 |

| 45 (+/- 0.3) | 2000 |

Special sizes can be manufactured based on customers' requirements.

| Element | Ni | Mg | Fe | Pb | Al | Bi | Si | Ca | P | Cu | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Concentration(%) | 0.0006 | 0.0006 | 0.001 | 0.0006 | 0.003 | 0.0006 | 0.003 | 0.0006 | 0.001 | 0.0006 | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Element | C | O | Sb | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Concentration(%) | 0.001 | 0.005 | 0.0006 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Purity(Metallic Base) Mo≥99.95% | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2. Performance advantages Of electrode purity molybdenum for electric glass melting furnace:

1). High-temperature corrosion resistance: Molybdenum electrodes can work stably at high temperatures, and have good corrosion resistance, and are not easily corroded by glass melt and high-temperature atmosphere.

2). High melting point: The molybdenum electrode has a high melting point, can withstand high temperature environment, and is not easy to melt and deform, thus ensuring the stability and durability of heating.

3). Uniform heating: The molybdenum electrode can provide uniform heating to ensure the consistency and stability of the molten glass temperature.

4). High thermal conductivity: molybdenum electrodes have good thermal conductivity and can conduct heat quickly.

3. Application:

Molybdenum electrodes are heating elements used in glass melting furnaces, usually in the form of straight rods or rods. It has high temperature corrosion resistance, high melting point and good electrical conductivity. Molybdenum electrodes can withstand corrosion and thermal stress in high-temperature environments, stably providing continuous and uniform heating.

The melting process of the raw material for wool and fiber production is always by electrical heating with electrode, especially designed plate and Rod electrodes are generally used.

We can provide stable quality Mo material with plate and Rod electrodes based on uniform density, purity and fine metal grain strength property.

Do you want to know more about our products?