Add to Cart

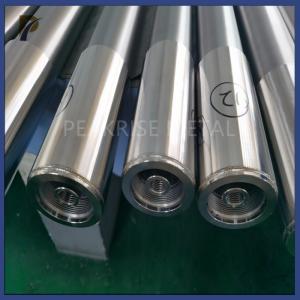

Dia50.8mm Molybdenum Dry-Type Electrodes In Stainless Steel Sheath For Glass Melting Furnace

1. Information Of Molybdenum Dry-Type electrode For Glass Melting Furnace:

The metallic bright silver-white surface of the molybdenum melting glass electrode will turn dark silver-white or uniform gray when exposed to room-temperature air. The molybdenum electrode with the highest purity of these has the best color and the least amount of surface alteration. Molybdenum electrodes can also be separated into: polished molybdenum electrodes, bright molybdenum electrodes, alkali washed molybdenum electrodes, buffing molybdenum electrodes and other types according to the processing method. The surface color of the molybdenum electrode is brown or dark brown after it has been machined, but this is not the color of molybdenum oxide; rather, it is the combined color of the numerous oxide impurities that the molybdenum electrode contains. The higher the quality, the lighter the brown will be and the better the surface's color consistency will be.

Molybdenum dry-type electrodes in stainless steel sheath,incorporating electrial insulation to prevent dissimilar metal to metal contact.

2. The Size Of Molybdenum Dry-Type electrode For Glass Melting Furnace:

The diameter of molybdenum electrodes commonly used in glass melting furnaces is 50mm,50.8mm,63mm,32mm,80mm, if you have other diameter,we also can process it as per your drawing.

Molybdenum electrodes with threads at both ends, one end male thread, one end female thread, if the customer does not request the thread size, our size is below:

| Dia63mm electrode | thread is M32, thread length 40~45mm |

| Dia32mm electrode | thread is M20,thread length 40~45mm |

If customer have request,we can process as per customer's drawing.

3. Chemical Content Of Molybdenum Dry-Type electrode For Glass Melting Furnace:

Usually purity is 99.95% Mo,our purity can do >99.97%

4. Quality Assurance Of Molybdenum Dry-Type electrode For Glass Melting Furnace:

We not only use good molybdenum powder, but also do 2~3 times of non-destructive testing in the whole production process to ensure that there is no crack inside the molybdenum rod.

Be sure to find professional people to solve professional problems. For molybdenum electrodes, find Peakrisemetal, quality assurance, good reputation, excellent after-sales service, you will not regret choosing Peakrisemetal.

Do you want to know more about our products?