Add to Cart

Heating Molybdenum Electrodes In Continuous Melting Furnace For The Production Of Optical Glass

1. Introduction of Mo electrode in melting furnace for optical glass:

Glass melting furnace technology is a technology that completely or partially replaces coal, oil, gas and other fuels to melt glass. Electrofusion glass technology has the advantages of saving energy and improving glass quality, and is widely used in the production of various glasses. Molybdenum electrode is an important part in the glass melting furnace, its density, uniformity and impurity content will greatly affect the service life of the furnace and the quality of the glass.

The continuous melting furnace used for the production of optical glass is a furnace with electric heating as the main part and gas heating as the auxiliary part. Molybdenum electrode is an important part of continuous melting furnace, and its quality is the key to the production of optical glass with excellent performance. The impurity content of the molybdenum electrode is also a key factor affecting the quality of the glass. Therefore, during the preparation of the molybdenum electrode, the composition of the raw material molybdenum powder must be strictly controlled. At the same time, the sintering process of molybdenum ingots is improved, and the content of C and O is reduced. In addition, it is very important to strictly control the cleanliness of the preparation workshop, operate strictly according to the process requirements, and prevent the contamination of molybdenum ingots by impurity elements. It can also reduce the impurity content in the electrode.

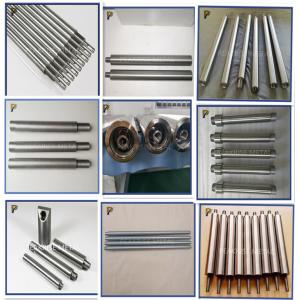

2. The size of Mo electrode in melting furnace for optical glass:

The overall requirements for molybdenum electrodes for optical glass melting furnaces are as follows:

specifications: Ø50±0.3×1000mm,

Ø50±0.3×1200mm,

Ø50±0.3×1300mm

Ø80±0.3×1000mm

We also can process as customer request and Design drawings.

3. Chemical and performance of Mo electrode in melting furnace for optical glass:

The overall requirements for molybdenum electrodes for optical glass melting furnaces are as follows:

chemical composition: Cr≤0.0017%, Fe≤0.0040%, Ni≤0.0013%, C≤0.0020%.

Curvature: 2.5mm/m, density: above 10.15g/cm3

| Chemical content: | |||||||||

| Cr | ≤0.0017% | Fe | ≤0.0040% | Ni | ≤0.0013% | C | ≤0.0020% | Ca | <0.0060% |

| O,Sn | <0.0050% | Al | <0.002% | Co | <0.0013% | Pb,Mg,Mn,Si | <0.0010% | Cu | <0.006% |

4. Process step of Mo electrode in melting furnace for optical glass:

The preparation process of molybdenum electrode for optical glass melting furnace is:

molybdenum powder-powder loading-cold isostatic pressing-sintering-extrusion-die forging-turning.

During the preparation process, the sintered molybdenum ingot has undergone ten die forging and two pressure processings, and the total processing deformation reaches 83%. Therefore, the prepared molybdenum electrode has a higher density and a larger specification size.

The primary products of Shaanxi Peakrise Metal Co., Ltd., a highly skilled manufacturer of tungsten and molybdenum non-ferrous metals, are tungsten-copper alloys, molybdenum-copper alloys, tungsten-molybdenum alloys, high specific gravity tungsten alloys, tungsten alloys, and molybdenum alloys and other more than 100 kinds of products.In 2010, with the surge in export sales of products in this industry, we began to focus on foreign trade export business,provide high-quality non-ferrous metal products for the international market.After years of development,at present, it has become a comprehensive non-ferrous metal production enterprise integrating manufacturing and processing, material research and development, product testing, stock inventories, too. Nearly ten years of growth serve as a reminder to us that providing high-quality goods and services will always be our first priority. At the same time, we are continuing to expand into new markets and serve more domestic and international clients while maintaining our high-quality standards. Exports of goods to Taiwan, the Ukraine, South Korea, the United States, Australia, Germany, and other nations have led to the development of enduringly positive business partnerships with clients. Customers give our products top marks for recognition and quality.

In addition to a variety of rolling mills, wire drawing machines, plasma welding rooms, lathes, milling machines, sawing machines, drilling machines, shears, stamping equipment, cutting equipment, grinders, straightening machines, CNC, etc., Peakrise Metal also has a variety of other production tools.

We will create records for each batch of items to record the complete situation from production to delivery to customer feedback, consequently boosting product quality and customer happiness. This will assure the traceability of each batch of products.

Do you want to know more about our products?