Add to Cart

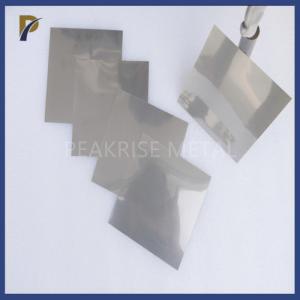

ASTM B386 Cold Rolled Molybdenum Sheet

1. ASTM B386 Cold Rolled Molybdenum Sheet Specification:

Molybdenum sheet has good thermal conductivity, little thermal expansion and contraction reaction, good electrical conductivity, and has become an important material in the electronic power equipment manufacturing industry, with good high temperature strength and creep resistance. Molybdenum is more ductile than tungsten and is both hard and soft. Tantalum and tungsten only have a higher melting point than molybdenum, which has a high modulus of elasticity. Molybdenum sheet are used in many specialty steels. Molybdenum electrodes, vacuum furnace applications, nuclear power, missiles, and airplane parts are a few more frequent usage.

2. Cold-rolled molybdenum sheet size per ASTM B386:

| Description | Grade | Density g/cm3 | Size (mm) | Application | |

| Large Size | High temperature molybdenum plate, molybdenum alloy sheet | Mo-La TZM | >9.8 | (20-40) x (90-240) x (200-600) | Good high temperature performance and machinability |

| High purity molybdenum sheet | Mo | 10.2 | Suitable for rolling pure molybdenum sheet | ||

| Small Size | High purity molybdenum sheet | Mo | 16 x 16 x 160 | Suitable for rolling molybdenum foil and molybdenum disc | |

3. ASTM B386 Cold Rolled Molybdenum Sheet Manufacturing Process:

Molybdenum powder---isostatic pressing---stamping rolling---induction sintering (guaranteed by hydrogen)---molybdenum sheet compact---hot rolling---annealing---basic acid washing---cold connection Rolling mill cold rolling---wide molybdenum sheet.

Of course, this is only one of the methods for the preparation of molybdenum sheet. There are other methods such as rolling, forging and casting.

4. Check For Flatness of ASTM B386 Cold Rolled Molybdenum Sheet:

An important thing in the production of molybdenum plate is to check the flatness of the surface of the molybdenum plate, which is a very important work. The following is the flatness inspection method of molybdenum plate:

The inspection of molybdenum sheet surface flatness is performed in accordance with ASTM B386 standard, all steel sheet over 0.5mm thick will exhibit a maximum flatness of 4% and 0.5mm thickness below 5%.

This is defined as:

High/Low value x 100 = Flatness - %. Where: high = maximum vertical distance between the flat reference sheet or plate surface and the lower surface; low = minimum horizontal distance between the highest point of the sheet or plate and the contact point of the flat reference surface.

Do you want to know more about our products?