Add to Cart

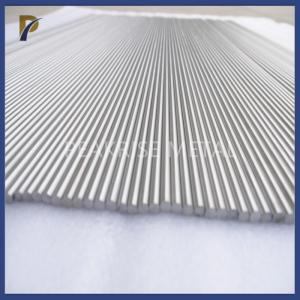

Mo-20%Re Molybdenum-Rhenium Alloy Rod

1. Description Of Mo-20%Re Molybdenum Rhenium Alloy Rod:

Molybdenum-rhenium alloy rod is an alloy composed of metal molybdenum as matrix element and alloying element rhenium. The alloy exhibits a rhenium effect that improves plasticity, and the rhenium content in the alloy is generally 11% to 50% (mass fraction).

2. Size Of Mo-20%Re Molybdenum Rhenium Alloy Rod:

Product name | Main grade | Main Size(mm) |

|---|---|---|

| Molybdenum Rhenium Alloy rod | Mo-20%Re Mo-41%Re Mo-44.5%Re Mo-47.5%Re | Φ1~Φ20×L |

Other size and content rate,pls inquiry for us,we can custom.

3. Performance Of Mo-20%Re Molybdenum Rhenium Alloy Rod:

From the chemical composition point of view, Mo has a melting point of 2622 °C and a boiling point of 5560 °C. It has the characteristics of high hardness, low thermal expansion coefficient, good high temperature strength, corrosion resistance and good electrical and thermal conductivity; Re has a melting point of 3180 °C and a boiling point of 5627℃, with excellent plasticity, mechanical properties, creep resistance, oxidation resistance, wear resistance and corrosion resistance. Therefore, the alloy composed of the two has the advantages of both molybdenum and rhenium.

According to different rhenium content, molybdenum-rhenium alloy rod can be divided into many types, such as Mo-20%Re, Mo-41%Re, Mo-44.50%Re, Mo-47.5%Re and Mo-50%Re, etc. Different types of products performance and specific use vary. Under certain conditions, with the increase of rhenium content, the plasticity, ductility and high temperature strength of alloy products are better. Generally, Mo-5%Re and Mo-41%Re are used as thermocouple wires and structural parts of flight equipment, and Mo-50%Re is used as high temperature structural parts.

4. Production method Of Mo-20%Re Molybdenum Rhenium Alloy Rod:

Molybdenum-rhenium alloy rod are generally prepared by double sintering method, powder metallurgy method or medium temperature sintering method.

The process route of the double sintering method is as follows: mixing molybdenum powder and rhenium powder, pre-sintering under pressure and temperature rise, vacuum sintering, and finally sintering under the protection of hydrogen into a molybdenum-rhenium sintered ingot.

The process route of powder metallurgy is as follows: mix molybdenum powder and rhenium powder, then pre-sinter into molybdenum-rhenium pre-sintered ingot, and then sinter at high temperature into molybdenum-rhenium sintered ingot.

The process route of the medium temperature sintering method is as follows: firstly reduce molybdenum oxide to molybdenum powder, ammonium rhenate to rhenium powder, then mix the two by ball milling, and then pressurize and sinter molybdenum-rhenium sintered ingots under the mixing of inert gas and reducing gas. That's it.

Matters needing attention: No matter which preparation method is used, there are high requirements for the purity of molybdenum powder and rhenium powder.

5. Application Of Mo-20%Re Molybdenum Rhenium Alloy Rod:

Molybdenum Rhenium alloy rod commonly used in the manufacture of filaments, X-ray tube targets, grid plates for microwave communication, high temperature furnace heating elements, high temperature thermocouples, reactor core heating tubes and protective plates, etc.